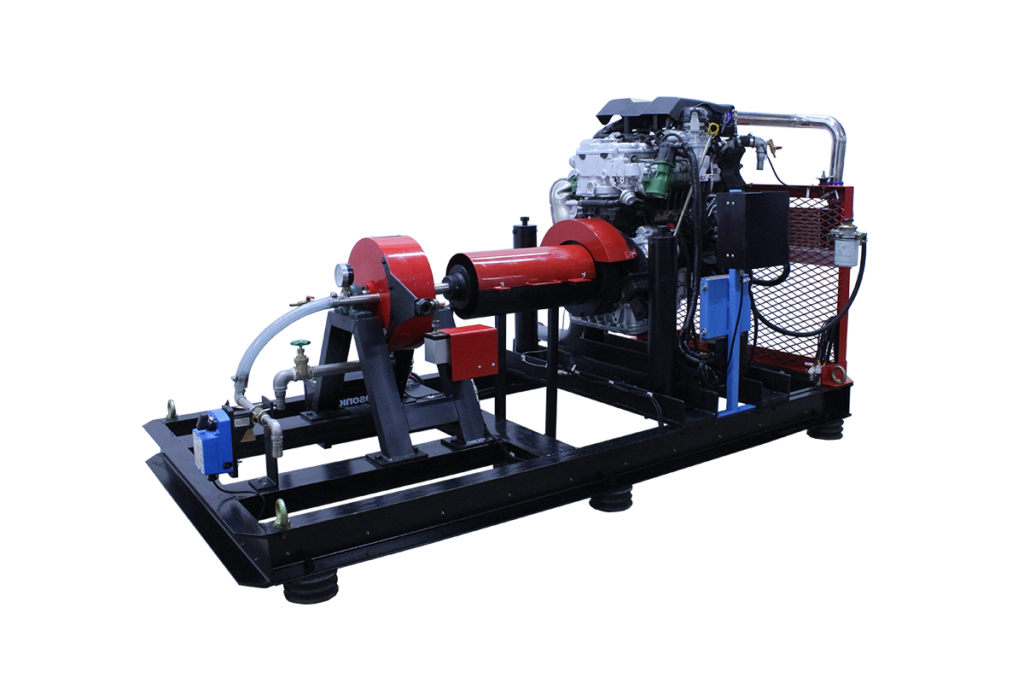

TH 150 MINI GAS TURBINE POWER PLANT

Enquiry

Video

Download

The unit is an educational two-shaft gas turbine power plant with a radial flow compressor and axial flow turbines, gear box, generator, and electrical loads as in the modern gas turbine power plant.

The first stage is a hot gas generator. Inlet air through an orifice flow measuring device is compressed by a single stage radial flow compressor. The turbine is motor started and runs on Jet A fuel. Fuel is injected by a fuel pump and ignited in the combustion chamber providing hot gas for a single stage axial flow turbine which in turn drives the compressor. The hot gas is discharged axially to a larger power turbine on the second shaft and exhausts to atmosphere. A fan is provided for cooling the gear box.

The power turbine output shaft is connected to the gear box. An alternator is connected to the gear box by a direct coupling. the electrical output is converted by an inverter to 220 VAC and the electrical power output is connected to a lamp load.

An Electronic Control Unit (ECU) controls the basic turbine operation. Additional instruments are provided for monitoring and controlling the plant operation and performance.

A touch screen computer with an interface unit and software are provided for speed and electrical load control, data display and analysis, and to assist the ECU.

Safety features include safety guard, gas generator over speed shutdown, power turbine over speed protection, power turbine entry over temperature shut down and emergency switch. The unit is floor standing with removable supports.

Instruction manual is also included.

Understanding the thermodynamic process.

Input power, output power and plant efficiency.

Mechanical power of gas turbine (optional)

| ||

| - Diffuser | : High strength aluminium | |

| - Combustion chamber | : Stainless steel | |

| - Bearings | : Ceramic ball bearing | |

| - Turbine wheel | : Vacuum cast inconel | |

| - Compressor | : High grade aluminium alloy | |

| ||

| - Running fuel | : Jet A or kerosene with jet oil | |

| ||

| - Turbine wheel | : Vacuum cast inconel | |

| - Interstage guide vane | : Stainless steel | |

| ||

| - Type | : Planetary | |

| - Lubrication | : Jet A | |

| : Approx. 1.5 kW power | |

| ||

| - Voltage conversion | : 12 VDC to 220 VAC | |

| : 600W with individual lamp switch. | |

| : Direct coupling | |

| : Electrical approx. 400 W | |

| : Mechanical approx. 700 W (required TH150-001) | ||

| : Engine cooling fan | |

| : Gear box cooling fan | ||

| : Engine exhaust duct | ||

| : 2 ear muffs | ||

| : Jet oil | ||

| : arometer | ||

| ||

| - Temperatures | : Ambient air, diffuser exit, gas generator turbine entry, power turbine entry and exit. | |

| - Pressures | : Diffuser exit, power turbine entry and exit. | |

| - Speeds | : Gas generator and gear box output shaft. | |

| - Voltage and current. | ||

| - Fuel flow rate. | ||

| - Air flow rate | : Differential pressure at inlet orifice. |

- Computer Interface unit with software for data display, analysis and control by computer.

- WiFi feature for data logging and real-time display remotely on smartphone (iOS and Android)

Power supply : 220V 1Ph 50Hz. Other power supply is available on request.

Net (unpacked) shipping dimensions WxLxH : 100x 125x 110 cm

Net weight : Approx. 165 kg

| Dynamometer for measurement of approximate mechanical power |

| - Modification of alternator to dynamometer for torque measurement | |

| - Torque sensor with signal converter | |

| - Additional software for torque and power readings. | |

| Silencer unit with stand |

| Dynamometer water cooling unit with pump instead of outside water supply. |

| - Capacity: 2 RT |

- Other optional equipment, please contact manufacturer ([email protected])