TH 413 STIRLING CYCLE HOT AIR ENGINE, Twin Power

Enquiry

Video

Download

The unit is for demonstration of stirling cycle hot air engine principles.

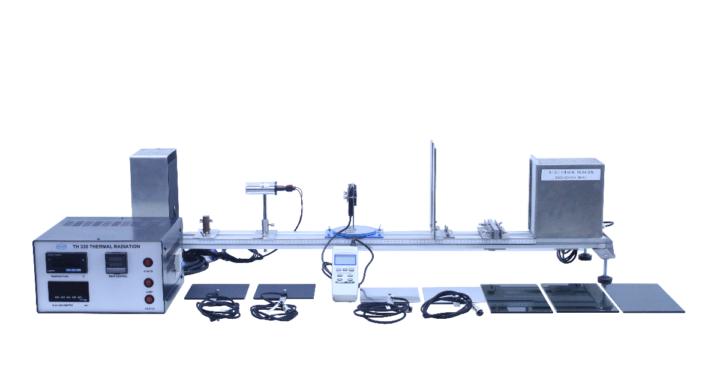

The engine consists of a large vertical cylinder with heater to generate hot gas. Twin cylinders above the hot gas cylinder generate power. The hot gas cylinder head can be cooled by water from a cooling system. All cylinders are attached to a common shaft. Heater to the hot gas cylinder can be varied.

Instruments are provided for measurement of input power and output power.

The advantage of this design is the ability to bring the engine to operating condition in a short time.

Instruction manual is also included.

Torque vs speed for a given input power.

Output and efficiency vs speed for a given input power.

Effect of hot gas cylinder head cooling on efficiency.

| Heater | : 500 W | |

| : Approx. 900 rpm | |

| : Up to 3000 mW with cooling water | |

| : Up to 2000 mW without cooling water | |

| : Water tank and pump | |

| ||

| - Torque | : Mechanical dynamometer with spring balance and weights | |

| - Speed | : Portable tachometer | |

| - Sensors with digital display | : Electrical input power | |

| : 220V 1Ph 50Hz. Other power supply is available on request. |

Net (unpacked) shipping dimensions WxLxH : 33 x 60 x 89 cm

Net weight : Approx. 23 kg

| Learning Software |

| to support both online/offline training with data calculation and analysis by manual data entry from analog measuring instruments. | |

| DC generator with resistive loads and voltage and current digital display for measurement of electrical power output |

| Computer Interface (computer not included) |

| This includes TH413S and significant sensor(s) instead of analog measuring instrument(s), | |

| data acquisition (capture, display, graph and/or data export), additional software function for real-time data logging with computer | |

| interface unit and WiFi feature for data logging and real-time display remotely on smartphone (iOS and Android) |

- Other optional equipment, please contact manufacturer ([email protected])

| Learning Software |

| to support both online/offline training with data calculation and analysis by manual data entry from analog measuring instruments. |