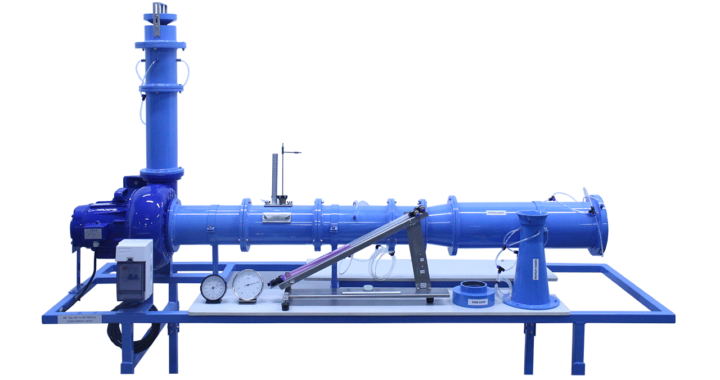

HF 135A PIPING LOSS APPARATUS

Enquiry

Video

Download

This is a comprehensive unit for studying the friction losses in pipes, pipe fittings, and valves; and to determine coefficients of discharge for primary flow measuring devices at various flow rates.

All friction loss components and the flow measuring devices are arranged on a water proof panel which is attached to a floor standing steel frame. The apparatus is to be used with a Hydraulic Bench (separately supplied) or an outside water supply.

Friction loss is measured by a pressure drop and coefficient of discharge is determined from a pressure drop and a flow rate. Flow rate is obtained from a water meter and a stop watch. The pressure drop is measured by differential pressure using manometer and differential pressure gauge. Pressure tapping in by small ball valves with quick connection. All pressure taps are connected by flexible hoses to a set of specially arranged manifolds such that differential pressure across any component can be measured simply by opening valves without removing the hoses.

The unit is on a steel frame with adjustable footings.

Instruction manual is also included.

Friction losses in straight pipes at various flow rates

Friction losses in pipe fittings, valves, sudden expansion and contraction at various flow rates

Friction losses in primary flow measuring devices and comparison of coefficients of discharge at various flow rates

| : Clear plastics | |||

- Venturi tube - Orifice plate - Pitot tube | ||||

| ||||

- Linear pipes, PVC - Linear pipe, stainless steel - Valves - Short radius bends - Long radius bends - Regular elbow - 45o elbows - 45o Y - Other components | : 3 different diameters : 1 : Gate, globe, ball, and check : 2 : 2 : 1 : 2 : 1 : Tee section, Inline strainer, Sudden expansion, Sudden contraction | |||

| ||||

- Flow rate - Differential pressure | : Water meter with stop watch : Water manometer with hand air pump : Differential pressure gauge | |||

- Net (unassembled) Shipping Dimensions WxLxH: 35 x 245 x 105 cm

- Net Weight: Approx. 99 kg

| Learning Software to support both online/offline training with data calculation and analysis by manual data entry from analog measuring instruments. |

| Hydraulics Bench, Neo or Hydraulics Bench (required accessory) |

| Variable area flow meter |

| Flow digital display |

| ISA nozzle |

| Additional polyethylene, Polybutylene, or ABS pipe |

| Additional galvanized steel pipe |

| Additional artificially roughened pipe |

| Additional annular pipe |

| Additional flexible hose with adapter |

| Differential pressure digital display instead of differential pressure gauge. |

| Mercury manometer instead of differential pressure gauge Note: Due to transport laws, mercury cannot be supplied. Buyer must source it locally. Approximately 50 cc or 700g is required. Filling kit is provided. |

| Portable differential pressure meter instead of differential pressure gauge |

| Portable differential pressure meter instead of water manometer |

| Pressure gauges at pump inlet and discharge for pump pressure vs flow rate curve |

| Computer Interface (computer not included) This includes HF135S and significant sensor(s) instead of analog measuring instrument(s), data acquisition (capture, display, graph and/or data export), additional software function for real-time data logging with computer interface unit and WiFi feature for data logging and real-time display remotely on smartphone (iOS and Android) |

- Other pipes and fittings can be supplied on request.

| : Learning Software to support both online/offline training with data calculation and analysis by manual data entry from analog measuring instruments. |