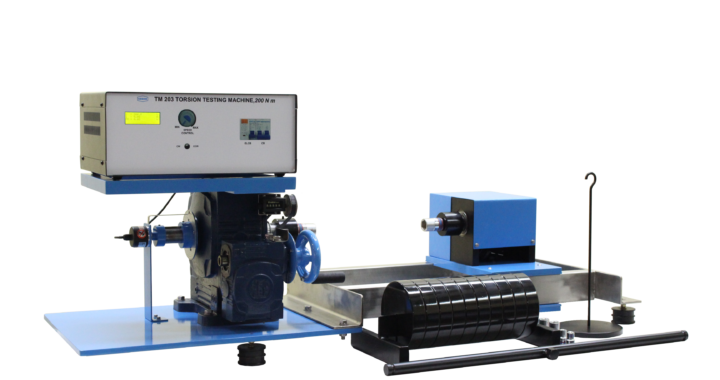

TM 203M TORSION TESTING MACHINE, 200 N-m.

Enquiry

Video

Download

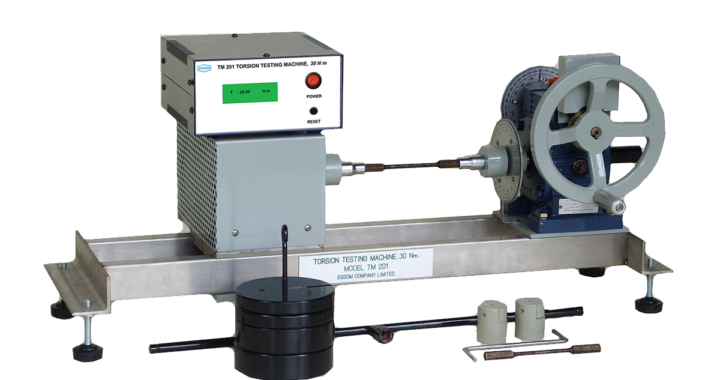

This is an educational machine for an extensive range of torsion tests.

The machine consists of a torque applying unit, and a torque measuring unit sliding on two parallel stainless steel tubes. The torque applying unit is reduction gear with a hand wheel, and angular displacement measuring instruments. The torque measuring unit has a torque arm with a two-direction load cell. The specimen is held at each end by hexagonal drive sockets which fit on the input shaft from the gear box and the torsion shaft. The torsion shaft column can be slided on two parallel guides to accommodate specimen length. The equipment is a table top type with adjustable footings.

Instruction manual is also included.

Relation of torque and twist angle under elastic deformation.

Determination of modulus of rigidity and yield shear stress.

Determination of modulus of rupture.

Characteristic of materials under plastic deformation.

Comparation of twist angle for forward-reverse directions.

Relationship between twist angle, length and size of specimens.

|

: 200 Nm |

|

: 3/4 in. square |

|

: 19 mm for hexagonal specimen |

|

: 350 mm. |

|

|

| - Revolution counter | : 5 digits |

| - Circular scale | : 360 × 1 degree graduation. |

|

: 0.1 N-m resolution. |

|

: 220V, 1 Ph, 50Hz. Other power supply is available on request. |

- Net (unpacked) Shipping Dimensions WxLxH: 65 x 170 x 50 cm

- Net Weight: Approx. 390 kg

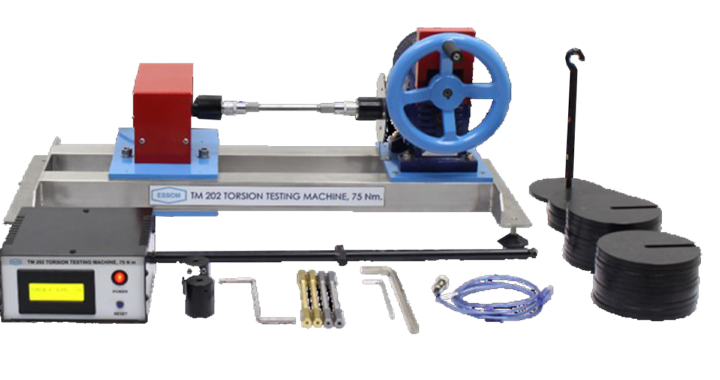

| Torque arm with weight hanger standard weights for torque calibration |

| Hexagonal head specimen |

| Angle digital display 0.1 degree resolution. |

| Chuck grips with a wrench for round specimen. |

| Computer Interface (computer not included) |

| This includes TM203MS and significant sensor(s) instead of analog measuring instrument(s), data acquisition (capture, display, graph and/or data export), additional software function for real-time data logging with computer interface unit and WiFi feature for data logging and real-time display remotely on smartphone (iOS and Android) |

- Other optional equipment, please contact manufacturer ([email protected])

| TM203MS | Learning Software |

| to support both online/offline training with data calculation and analysis by manual data entry from analog measuring instruments. |