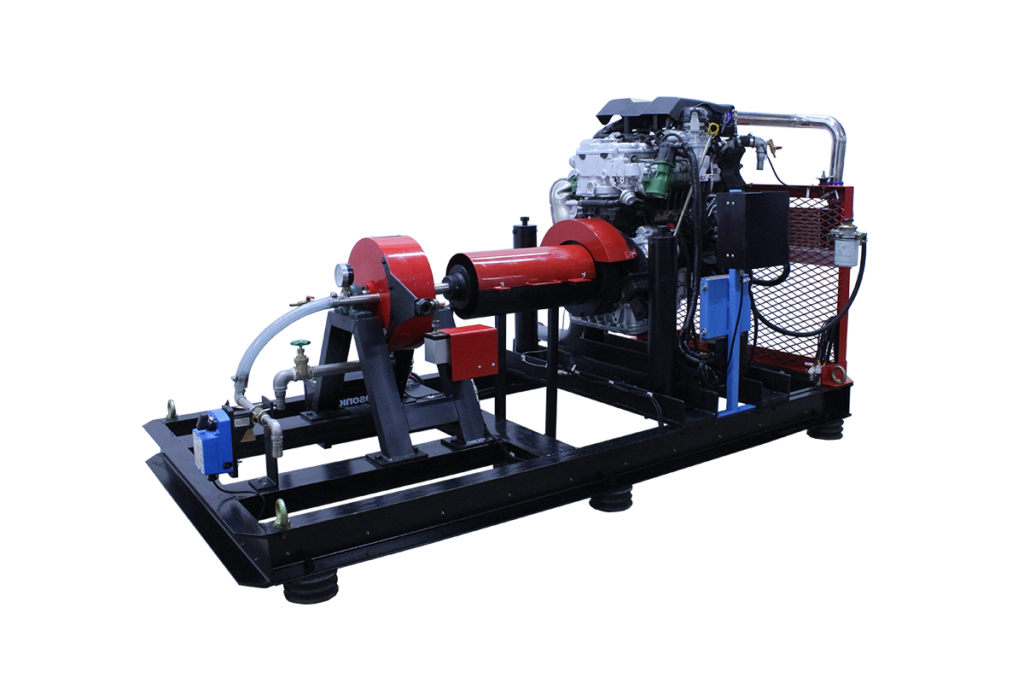

HP 301 SERIES AND PARALLEL PUMP DEMONSTRATION UNIT, Computer Interface

Enquiry

Video

Download

This is a bench top unit for studying the series and parallel pump characteristics with data analysis by computer.

The unit consists of two sets of industrial centrifugal pump and a motor, a PVC storage tank on a steel base, inverter, sensors and software. One pump speed may be varied by advanced inverter while the other pump speed remains normal. By manipulating flow control valves, each pump can be operated individually or both pumps connected in series or parallel.

HP 104 Advanced inverter with computer interface unit is required but separately supplied.

Instruction manual is also included.

Flow rate vs head at various speeds for one pump

Flow rate vs head for two pumps connected in series or parallel

Power input, output and overall efficiency at various speeds for one pump

| |

| - Maximum flow rate | : 80 LPM |

| - Maximum head | : 18 m water |

| : 1 |

| : HP104 (separately supplied) |

| : Pressures for pump suction and discharge | |

| : Speed and motor input power |

- Software for data display and analysis by computer (separately supplied)

- WiFi feature for data logging and/or real-time display remotely on smartphone (iOS and Android).

- Net (unassembled) Shipping Dimensions WxLxH: 60 x 110 x 70 cm

- Net Weight: Approx. 66 kg

| Advanced inverter with computer interface unit (required accessory). |

| Water temperature sensor |

| Additional advanced inverter for the second pump with speed and motor input power display |